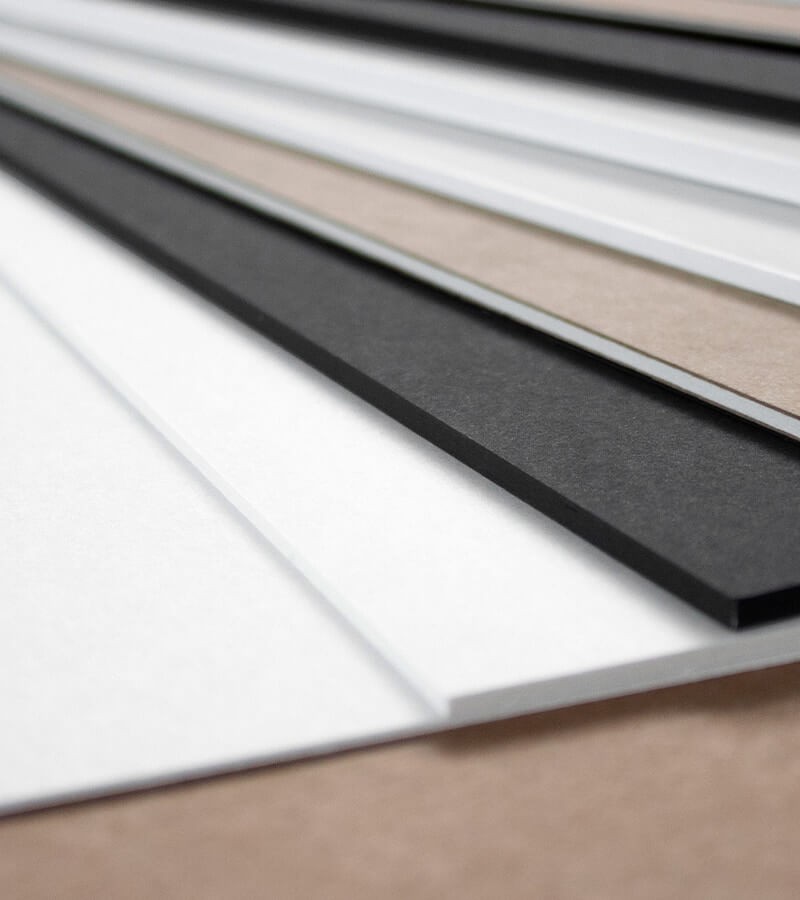

GATORFOAM® (Lightweight foam boards)

Double sided black or white lightweight foam boards with extreme stability and therefore ideal for laminating or mounting large format prints and photos.

High dimensional stability | Resistant | Low weight

starting at €655.75*

% €0.00 (- %)Free shipping

Currently not available. Please ask for delivery time.

This product will be released on 26 April 2024

In stock. Delivery usually within 2-3 working days

Currently not available.Please ask for delivery time.

{1} Available in 1 day, delivery time In stock. Delivery usually within 2-3 working days|]1,Inf[ Available in days, delivery time In stock. Delivery usually within 2-3 working days

Extremely stable lightweight foam boards ideal for lamination!

Composition:

Sandwich panel with resin-impregnated top layers on both sides made of special cellulose laminate (black or white) and a colour-matched polysytrol foam core.

Applications:

Due to the hard and resistant surfaces, GATORFOAM® panels have excellent stability and are ideal as a carrier board for laminating large format prints and photos. They are also used for a variety of other advertising purposes such as signage (indoor), POS / POP displays, 3D applications (logos and lettering), shop design, hanging signs and life-size figures, as well as by architects, shop fitters and trade fair constructors. Are you a photographer? In this case our one-side black / reverse side bright white plates for V-Flats are the ideal accessories for your studio.

Further processing:

GATORFOAM® lightweight boards can be optimally processed: The unique bright white surface ensures excellent printing results and optimum image quality in digital printing (large format flatbed printers). The surfaces are also suitable for the use of ultra violet printing inks in screen printing. GATORFOAM® is also sprayable and brushable. The lightweight foam boards can be cut by simple mechanical processes with standard wood and plastic cuttingg tools: saws (band saw, pendulum jigsaw, circular saw), milling and water jet cutting. By using the right types of adhesive, printed papers and foils can be laminated onto the panels with excellent results.

Hot lamination:

- Max. temperature must not exceed 90 °C

- Max. pressure on the GATORFROAM panel: 1bar

- Max. time of 3 min. should not be exceeded

- Boards thicker than 10 mm should be heated before lamination

Cold lamination pressure sensitive adhesive:

- Commercially available SK-foils can be used for cold lamination

- Before laminating, the board should be allowed to reach room temperature for best results

- If machine lamination is used, care must be taken to use the appropriate materials

- GATORFOAM white should be roughened before lamination

(Special) sizes & freeforms:

As a leading 3A distributor we offer GATORFOAM® in various sizes.

Special sizes and other thicknesses are available on request.

We are happy to cut individual blanks or free-forms according to your specifications: cutting service.

Further features:

- Cover layers are resistant to commercially available water-based and UV-curing inks; not suitable for solvent-based adhesives and inks.

- The foam core is not resistant to solvents, solvent-based adhesives and hot-melt adhesives.

- Meets the following standards: DIN ISO 9001:2008, DIN ISO 14001:2004 and BS OHSAS 18001:2007

Downloads:

Thickness: |

5.0 mm |

|---|---|

Grammage: |

1120 g/m² |

Stock format: |

1220 x 2440 mm, 1525 x 3050 mm |

Type of Material : |

Lightweight foam board, Sandwich board |

Surface/Layers: |

Polystyrene (PS) |

Color: |

Black, White |

Inlay/Core: |

Polystyrene (PS), Black, White |

Printing processes: |

Digital printing, Screen printing |

Further processing: |

Laminating, Milling, Sawing |

Application/range of use: |

Decorations, Displays POS/POP, Exhibition stand construction/shopfitting, Figurines, Furniture construction, Hanging signs, Interior design, Lamination substrate for prints & photos, Posters, Shop window design, Signs, Stands |

Special features: |

Low weight |

Manufacturer: |

3A Composites |

Origin: |

USA |

Here is an overview of the grammages, thicknesses and formats we have in stock.

Special formats and/or special thicknesses are possible on request.

Surfaces white, core white

| Grammage (g/m²) | Thickness (mm) | Available format (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1120 | 5 | |||||||||

Surfaces black, core black

| Grammage (g/m²) | Thickness (mm) | Available format (mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1120 | 5 | |||||||||